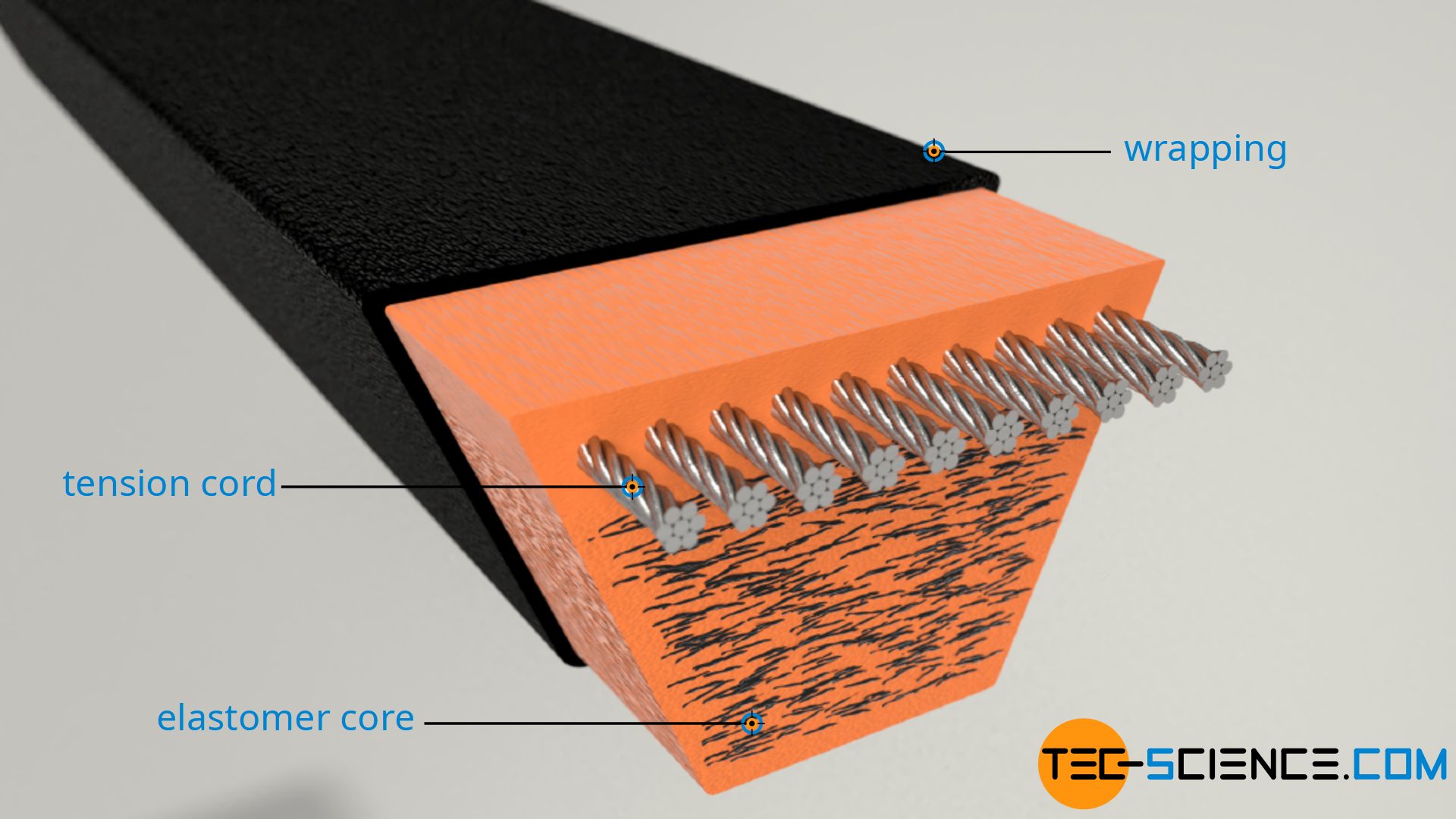

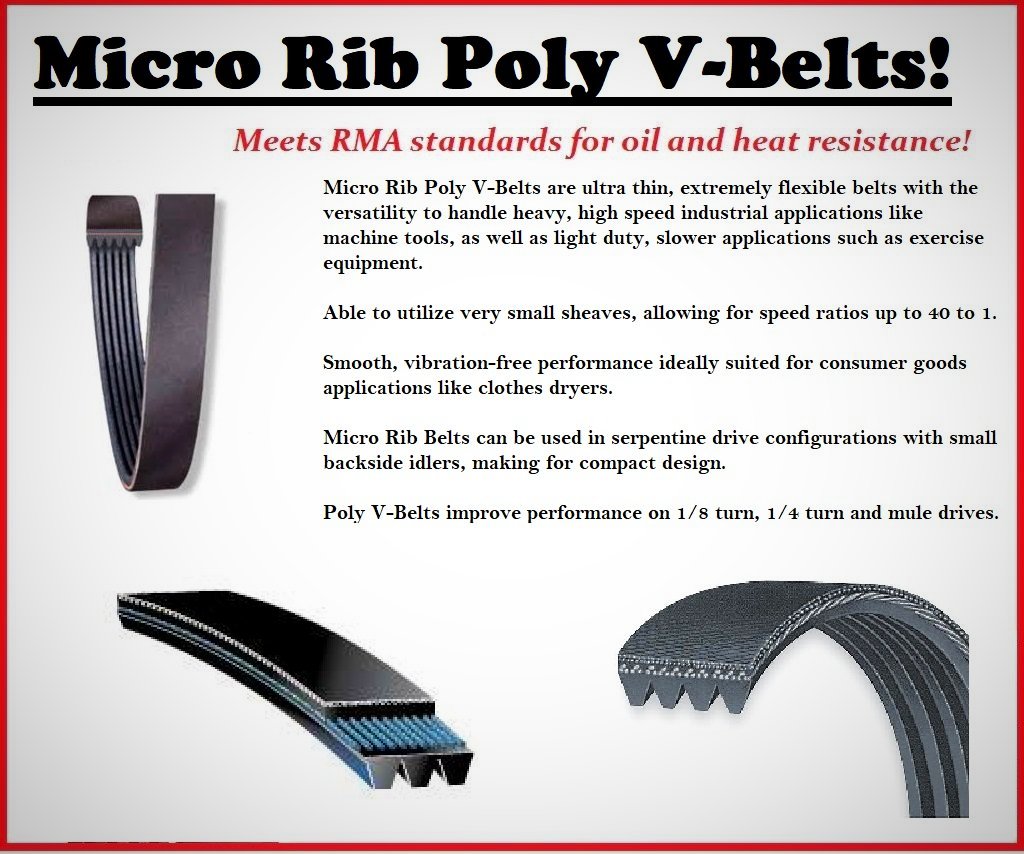

7 Ribbed Belt type PH, PJ, PK, PL, PM and so on Applications Our Ribbed Belts are used for carrying wet, loose sand and grain materials in bugs The vshape of the chevron cleats prevents the material from sliding back Specification Our Ribbed Belt feature 1 Flexible cover fabric supports lateral stiffness to protect tension members VRibbed Belts The Vribbed concept combines some of the best features of flat belts and VbeltsApplication of Multi V Ribbed Belt SHENWEI MultiRibbed Belt are specially designed for engine drives Compact drives with high speed ratios, drives requiring minimum maintenance, drive in a noise sensitive environment, for serpentine drives and drives with reverse bend idlers like household appliances, work tools, machine tools etc

Serpentine Or V Belt Driving Your Accessories Chevy Hardcore

Ribbed belt vs v belt

Ribbed belt vs v belt-Ribbed Belt Pulleys for Taper Bushes, Profile PJ 3841 Ribbed Belt Pulleys for Taper Bushes, Profile PL 4246 Ribbed Belt Pulleys for Cylindrical Bore, Profile PJ 47 Ribbed belT PulleysVBelts will transmit power satisfactorily over a wide range of tensions An experienced user can develop a "feel" when a drive is tensioned within this range However, in order to optimize belt life and performance and to avoid undue stress on shafts and bearings it is desirable to calculate and measure belt tension based on drive loads This standard provides a method for calculating and

V Ribbed Belt Automobile And Motorcycle Transmission Belts Mitsuboshi Belting

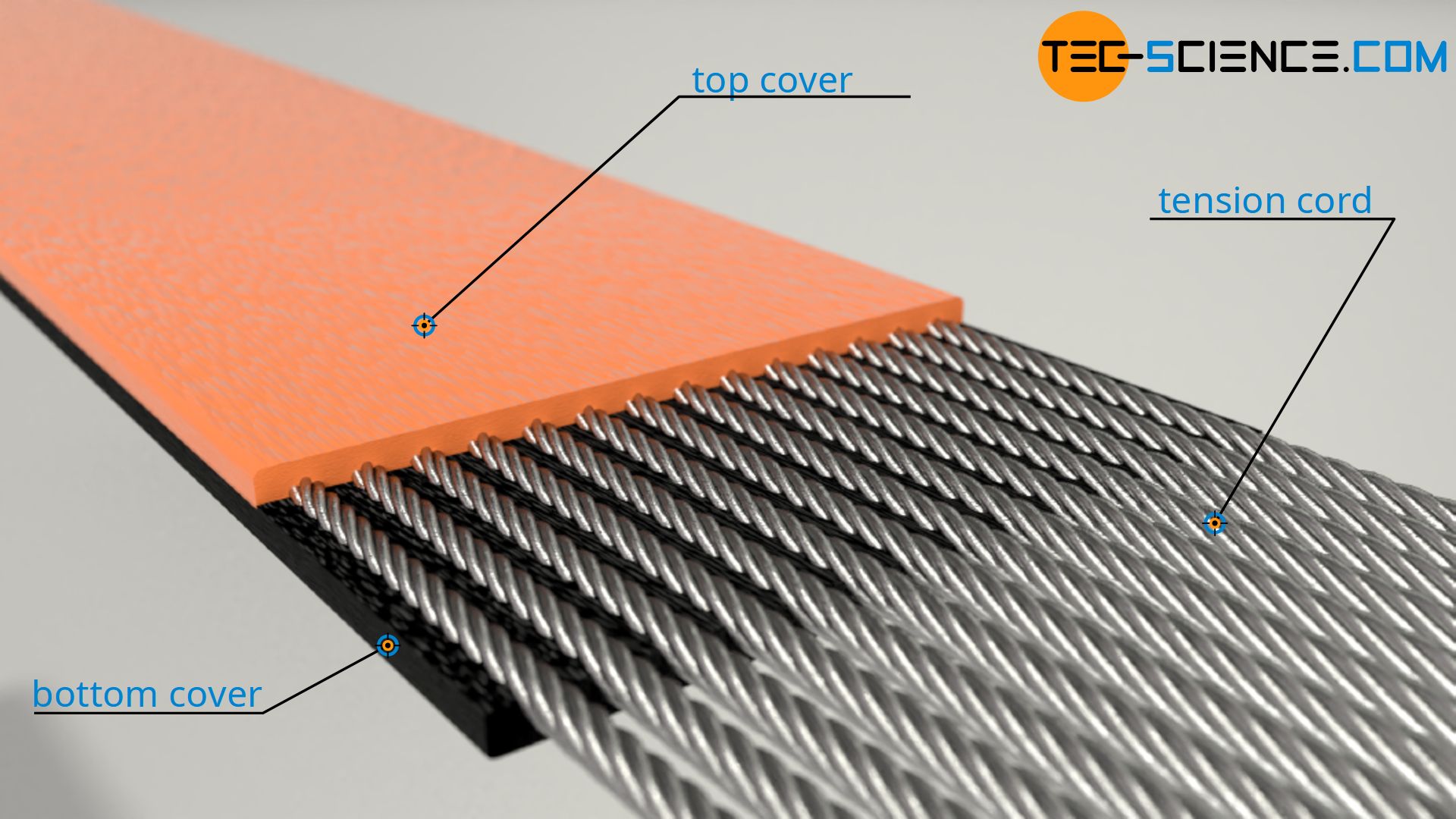

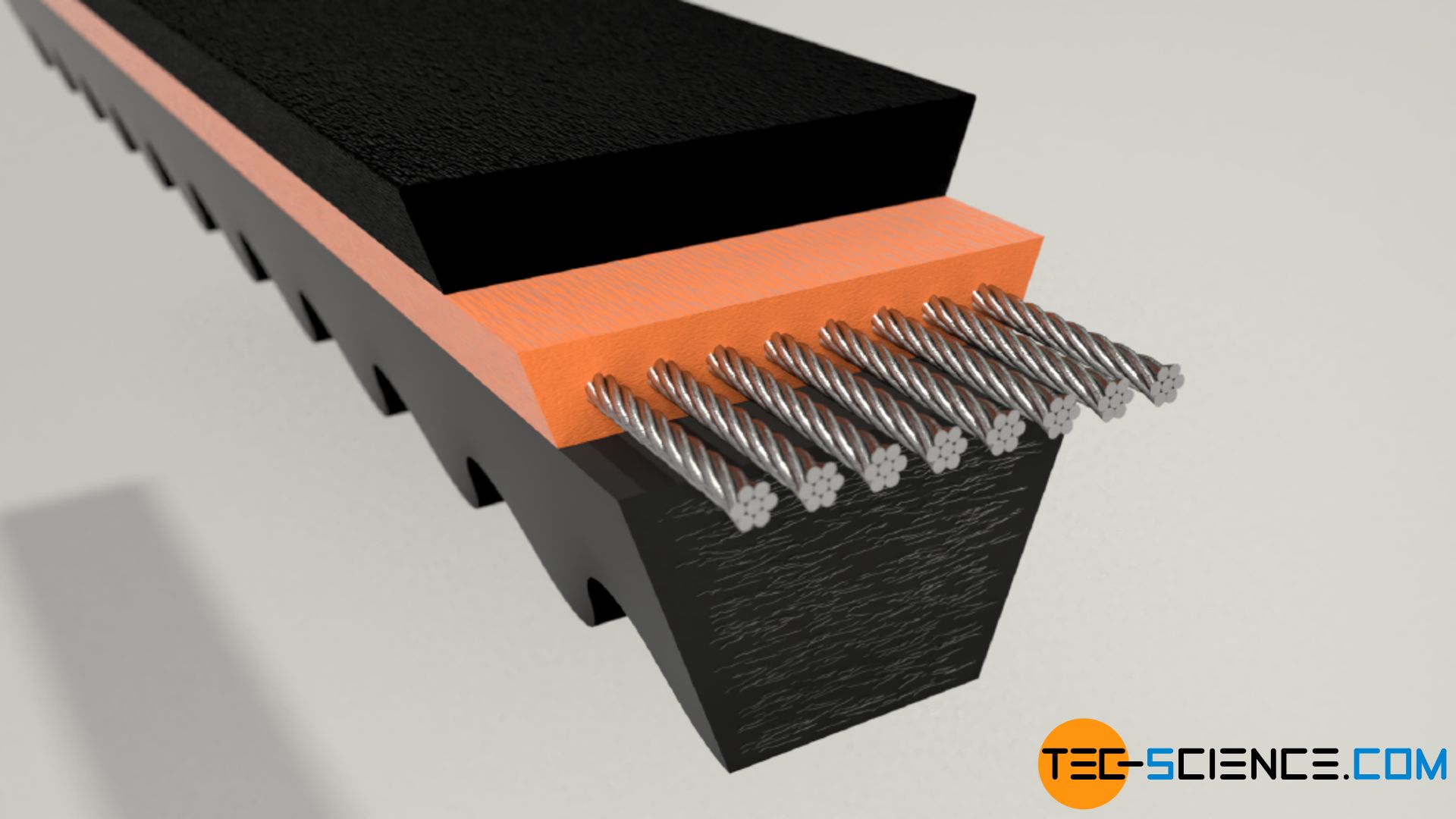

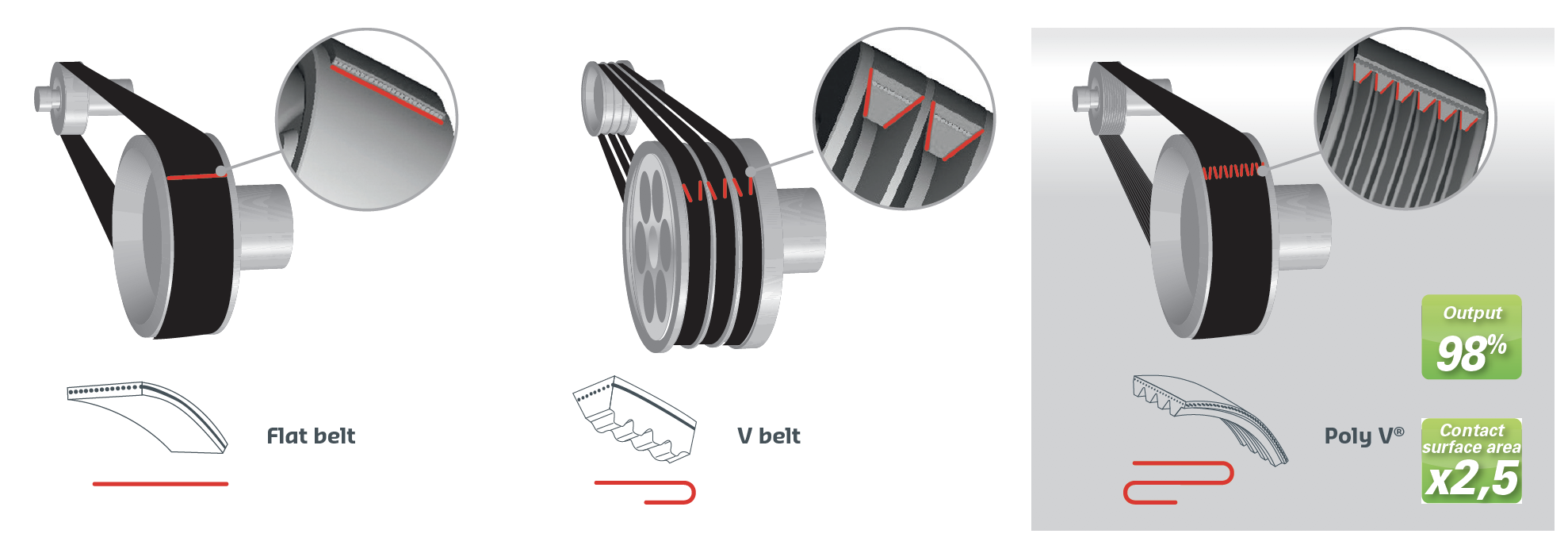

A V belt's most important element — its tensionbearing top — includes fiber cords for strength to bear the actual traction load Modern tensionmember cords are often aramide, polyester, fiberglass, or even steel Prestretched variations help minimize stretch The cords embed into the main belt material that serves to hold the belt body together and shed heat TheRegistered Member 9/23/ PM 22 replies RM Registered Member Follow I was asked recently if I knew why someone would use a "Power Band" (single outer cover, and I think power band is a Gates brand)) belt instead of multiple single "V"'s on a drive I haven't been around very many of the power Vbelts Vbelts use a trapezoidal cross section to create a wedging action on the pulleys to increase friction and improve the belt's power transfer capability Joined or multiple belts are specified for heavy loads Vbelt drives can have a peak efficiency of 95 percent to 98 percent at the time of installation Efficiency is also dependent on pulley size, driven torque, under or

Flat belts are not necessarily more efficient than VBelts It depends on what you are trying to do with the belts From a textbook, classroom perspective, flat belts transmit more power, more efficiently than V Belts when each can be used in the sVbelts run smoother and quieter, last longer and substantially improve energy efficiency compared to noncogged belts Hex belts, also known as double Vbelts, are designed for use on drives with one or more reverse bends They usually transmit power from both sides of the beltReplace VBelts with Notched or Synchronous Belt Drives Approximately onethird of the electric motors in the industrial and commercial sectors use belt drives1 Belt drives provide flexibility in the positioning of the motor relative to the load Pulleys (sheaves) of varying diameters allow the speed of the driven equipment to be increased or decreased relative to the motor speed A properly

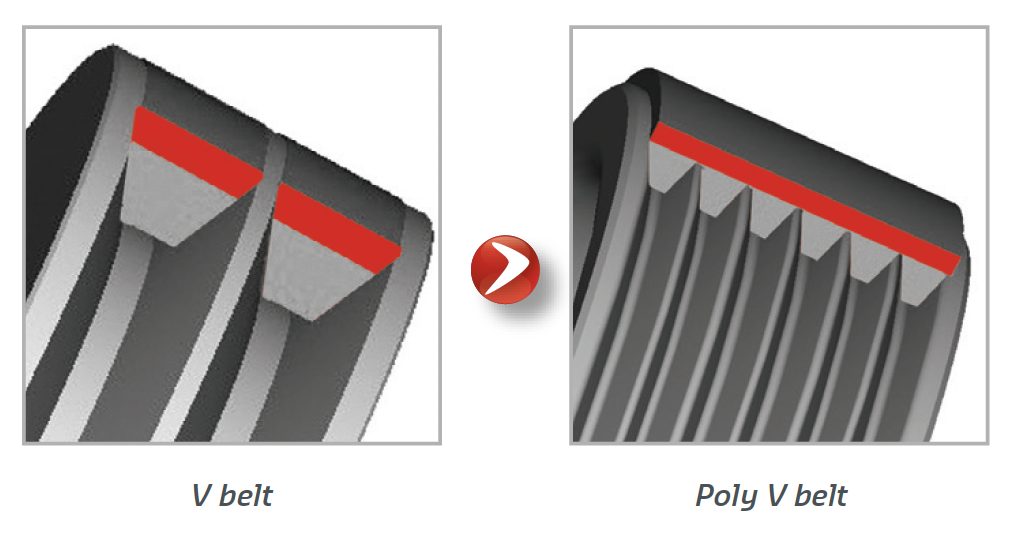

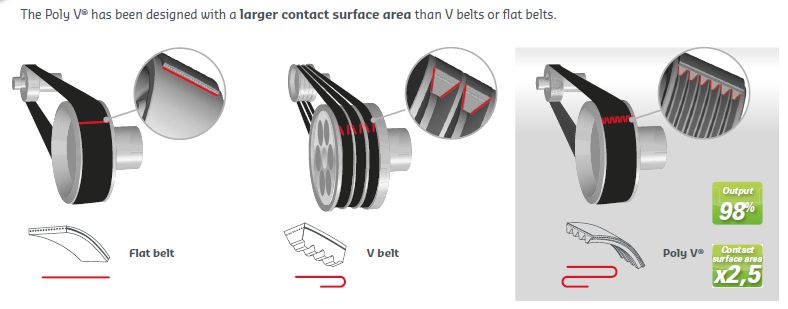

Just measure the top width and circumference, find another belt with the same dimensions, and slap it on the drive There's only one problem that approach is about as wrong as you can get Like their synchronous belt cousins, Vbelts have Designed to have a larger contact surface area than that of the traditional Vbelt or Flat Belt, the Poly V belt can operate at a minimum pulley diameter of just 9mm, compared to a minimum pulley diameter of 50mm with a traditional Vbelt Improved transmission ratio is also possible (Poly V 160 vs Vbelt 1) removing the need for stepped pulleys In addition to theseThe Vbelt drive cannot be used for long distances due to greater weight per unit of length They are not applicable to the synchronous machines because they are not free from creep The centrifugal tension prevents the use of belts at speeds below 5 m/s and above 50 m/s The construction of pulleys for vbelts is more complicated than the flat belt Read Flat Belt Drive

Guide To V Belt Selection And Replacement Pte

Amazon Com Acdelco Professional 6dk729 Dual Sided V Ribbed Serpentine Belt Automotive

No need to as you can convert your iphone or android to a profess Another V belt is also found to drive the airconpulleyfromthe same crankshaftpulleyWorn out belts can be visually inspected by their look or by slackness beyond tension adjustment Vbelts were the standard accessory alt, Power steering, WP, AC drive belt before the serpentines The V belt connects all of your pulleys, runs your alternator, air conditioner, water pump etc A V beltV ribbed belt kits for commercial vehicles are also new Ebenfalls neu sind d ie KeilrippenriemenKi ts für Nutzfahrzeuge Singlestage, maintenancefree s teelribbed belt driv e in a spring supported drive unit Einstufiger, wartungsfreier Keilrippenriemen in gefederter Antriebseinheit

Serpentine Or V Belt Driving Your Accessories Chevy Hardcore

Ribbed Belts Poly V Belts Multi Rib Belt Distag Quality Component Solutions

VRibbed Belt Round Belt (Square Belt) Special Belt D i r e c t C o n n e c t P o w e r T r a n s m i s s i on Coupling Generaluse, Office & Home applia nces, agriculturaluse O fic eapl i n, rs omh y Agricultu raluse (for straw conveyor) A g ric ult al se(f ovb h ) Gener alIndustries GeneralIndustries, agricult uralmachin ery Ofic e & Home appliance,gen er aluse Automotive use Ofice & HomeSee the entire survey Q What are some of the applications you have used Vbelts and Vribbed belts for?Vbelts look like relatively benign and simple pieces of equipment They're basically a glorified rubber band, right?

Poly V Belt For Industry Hutchinson Belt Drive Systems

Gates 540l6 Micro V Belt L Section 540l Size 54 Length 1 1 8 Width 6 Rib Industrial V Belts Amazon Com Industrial Scientific

V belt fan might encounter belt slippage, excessive wear to sheaves Cog belt fan would be louder, possibly break motor shaft or fail motor DE bearing Bend fan shaft or fail DE fan bearing I'm lazy, I'll take the consequences of the V belt fan 4 Was on a roof last year, 5 large exhaust fans, customer had replaced V belt drives With cog belts and shaves 1 fan had broken motor shaft, 1 fan34 answers Answers Commercial and industrial, Air Handlers, Blowers, Exhaust fans as well as anything with a v belt set up Including my own lawn mower ~Keith H, HVAC Mechanic / Forman, Durham, Durham32,50 all prices incl VAT, plus Shipping costs

Timing Belt Cogged V Belt Ribbed Belt

Robotic Mechanisms Pulleys And Belts Robotpark Academy

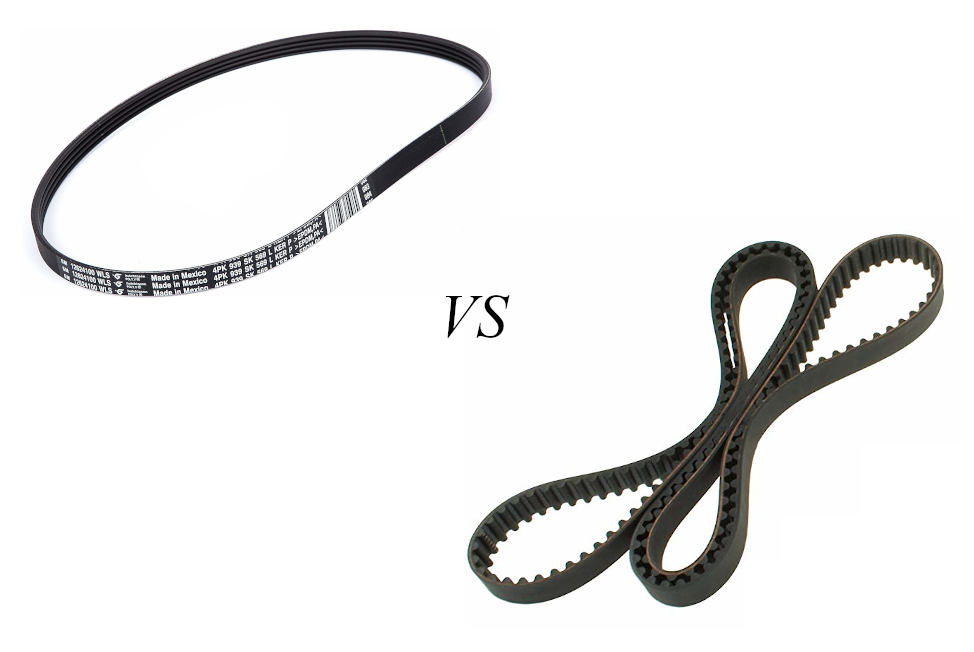

Multi Ribbed Belts combine the high flexibility of flat Belts with a higherpower transmission capacity than the traditional V Belt Multi Ribbed Belts enable economic solutions even under difficult drive conditions, such as large transmission ratios, high belt speeds, small diameter pulleys and drives with back idler pulleys The belts consist of multiple Vribs that mesh into the grovesVribbed belt or multigroove belt has a specially constructed shape Angle 40 degree that tracks in the mating groove of the pulley or sheave in power transmissions As the load increases the belt wedges in the groove which helps improve torque transmission It's commonly produced using neoprene rubber or polyurethane If playback doesn't beginV belts also derive their name from the crosssection of the belt itself In the first photo above a V belt will ride in grooves on the pulleys Serpentine belts don't have this same crosssection because as you can see in the 2nd photo both sides of the belt

Dayco Poly V Serpentine Belts

1

VBELT DRIVES This technical manual contains all important technical information and methods for the design and calculation of drives with Optibelt Vbelts and Vgrooved pulleys for industrial applications Our Application Technology experts offer you free support service regarding the application of our products and also help solve your drive problems Especially regarding largeCarlisle Belts by Timken Have a New Name Timken Belts — The Timken Company, a world leader in engineered bearings and power transmission products, announces today that Carlisle® brand belts will now officially go to market as Timken BeltsVolvo Genuine 41,15 Vribbed belt DPK 1853 mm 6 Ribs Volvo C70 (05), S70 V70 (00), V70 XC (00) Vehicle equipment for vehicles with Air conditioner ;

Gates 11l12 Belt Micro V 12 Rib Belt 112 Inches 9173

What Is A Serpentine Belt When Should You Replace It Virginia Tire Auto

Ribbed Belts (Poly Vbelts) In many more sophisticated drive systems there is a requirement for high power ratings, combined with compact drive design This led to the development of Ribbed Belts, which combine the advantages of high flexibility with excellent power transmission Additional Information Ribbed Belts are cut to size to depending on type and size and are alsoBearingtech supply a large range of V Belts, this page will guide you through the process of identifying what v belt or drive belt you need in an easy to understand format and will allow you to purchase the Vee belt you need Each Wedge shaped belt is separated into it different sections or types for an easy and simple shopping experienceStretchElastic Ribbed Belts are pretensioned over the pulleys to maintain tension and transmit power more efficiently over a longer time This removes the need for tensioning devices with a simple and troublefree belt installation Combining the performance of vbelts with the stability of flat belts Elastic Stretch Ribbed Belts are

V Belts And V Ribbed Belts Selection Guide Types Features Applications Engineering360

Types Of Belts For Belt Drives Tec Science

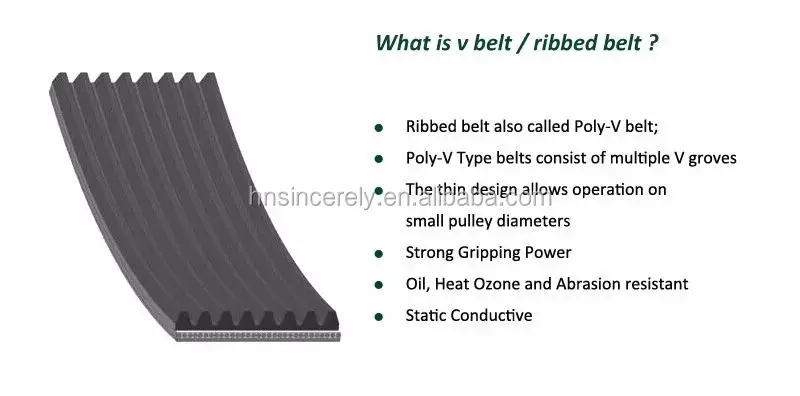

The ribbed vbelt is a single endless belt with longtudinal vshaped ribs that match grooves in sheaves It combines the flexibility of thin, flat belts with the strong gripping traction of conventional vbelts thin construction – highly flexible increased flexibility – minimize bending stress less bending stress – longer belt life The ribbed vbelt offer an uniterrupted tensile cord That's pushing it pretty hard for a 1/2" v belt If you don't go with the ribbed belt I'd recommend a 3/8" cogged v belt (replace the pulleys, of course) Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but not likely with link belts) Reactions intjonmiller M mattthemuppet2 HM Supporter GoldYou don't have a Dayco krikit tool or other professional equipment to measure belt tension?

Ribbed Belt Ph Pj Pk Pl Pm Tempo International Rubber

V Ribbed Belt Automobile And Motorcycle Transmission Belts Mitsuboshi Belting

SHENWEI Agriculture Ribbed Belt are specially designed for combine harvester fan drives, best fit for CHN, CLAAS, JOHN DEER, CASE, ROSTALMASH etc combine harvester INQUIRY Please Feel free to give your inquiry in the form below We will reply you in 24 hours! Your Name* Your Email* Your Phone Number Your Country Your Requirement* Follow Search for Products Agricultural BeltsMultiribbed belts, ribbed belts, v ribbed belts, Automotive Ribbed Belt, industrial belt and rubber ribbed belts are designed to allow the usage of both the ribbed and the flat sides for transferring power, helping them replace several traditional belts resulting in a substantial reduction in operating costs and increasing drive reliabilityVRibbed Belts combine the benefits of flat belt flexibility with a vbelt's power transmission capability VRibbed Belts provide the ultimate in belt design for use on today's modern engines where space and weight are critical Accessories can be driven from the top or bottom side of the belt enabling compact designs Top or backside ribs are capable of handling high load

China Ford Focus Multi V Belt Focus 05 12 2 0 5pk705 Ribbed Belt China Ford Focus Multi V Belt Fan Belt

Gates K Serpentine Belt Equivalent 750k8 8 Rib Poly V Belt Mechanidrive

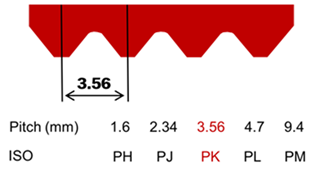

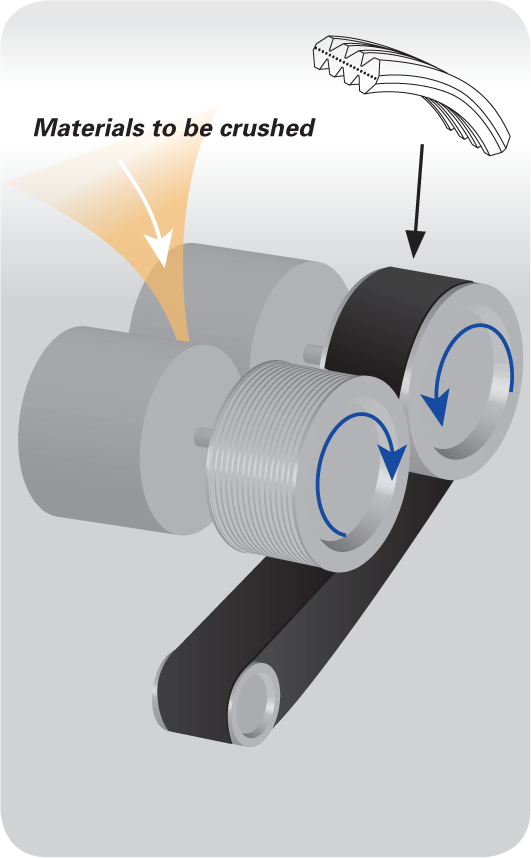

Toyota Tundra 10, FleetRunner MicroV™ Heavy Duty VRibbed Belt by Gates® Belts are engineered to save your fleet money and lost service time Patented EPDM construction with distinct green overcord built specifically for more durability, superior flexibility, stability, and longer life on heavyduty drives Haul moreRibbed belts have lengthwise grooves on the inside Measure the pitch of the groove, ie distance between projections, eg 354 mm = belt type PK Count the number of grooves, ie the number of projections eg 7, as shown in the pictureSelect PolyVBelt or Consult Your Selection Step 2 What Is the Ribbed Belt Profile and Number of Ribs?

Multiple V Ribbed Belt 8pk1440 Optibelt Agro Power Oem 0 For Claas Order At Online Shop Agrodoctor Eu

Selecting The Right Micro V Belt Gates Europe

Multigroove belts A multigroove, VRibbed, or polygroove belt is made up of usually between 3 and 24 "V" shaped sections alongside each other This gives a thinner belt for the same drive surface, thus it is more flexible, although often wider The added flexibility offers an improved efficiency, as less energy is wasted in the internal friction of continually bending the belt InThe friction is multiplied by the mechanical advantage of the wedging principle Correct VBelt tensioning is the single most important factor necessary for long, satisfactory operation How you tension a belt at installation will determine how long the belt will run Too little tension results in slippage, excess heat, and premature belt & pulley wear TooEmailinfo@sanfortechcom Cell phone 0086 V belt, timing belt, ribbed belt, VS belt, harvester belt, banded belt, rubber belt, PU belt, drive belt Powered by MetInfo 613 ©0021 MetInfo Inc About

Duralast Belt

V Ribbed Belt Automotive Repair Mitsuboshi Belting

BELT ID CHART Single VBelts Predator® VBelts SPCP Aramid tensile cords provide superior service on high impact, shockloaded drives AP BP CP 5VP 8VP SPBP 1/2" 5/16" 21/32" 13/32" 7/8" 17/32" 7/8" 5/8" 1" 16mm 22mm 35/64" 13mm 18mm Super HC® VBelts Single "V" Belt vs "Power Band", what is difference?MultiRibbed VBelts combine the highperformance power transmission properties of VBelts with the outstanding stability of Flat Belts Featuring Vshaped parallel ribs engineered from premiumgrade and polyutherane materials Ribbed Belts are well suited to drive systems where conventional VBelts are challenged Including compact drives, highspeed drives, Serpentine

Symptoms Of A Bad Or Failing Ac Belt Yourmechanic Advice

Gates 840l8 Micro V Belt L Section 840l Size 84 Length 1 1 2 Width 8 Rib Industrial V Belts Amazon Com Industrial Scientific

Vbelts operate on friction;Vribbed belt DPK 1853 mm 6 Ribs Volvo C70 (05), S70 V70 (00), V70 XC (00) Vehicle equipment for vehicles with Air conditioner;

Serpentine Belt Wikipedia

Drive Belt V Belt Iveco Stralis Trakker Cursor 8 10pk1725 Auto Ricambi Eu

China Poly V Belt Pj Belt China Poly V Belt V Ribbed Belt

Machinery Parts Installation Warranty Of Nylon Belting Ribbed V Belts Taper Bush Sheaves Flexible Coupling

Ribbed Belts Poly V Belts Multi Rib Belt Distag Quality Component Solutions

China Ribbed V Belt 6pk755 755mm 6ibs Fan Belt China Ribbed V Belt V Ribbed Belt

V Belts Direct

Serpentine Belt Vs Timing Belt What Are The Differences Car Super Care

7pk1275 Automotive Serpentine Micro V Belt 1275mm X 7 Ribs Automotive Serpentine Belt Metric 7pk1275 Serpentine Belt Nissan 117eb300 Nissan 117eb30a Nissan 117eb310 Nissan 117eb70c

How To Properly Check A Serpentine Belt Youtube

China Oft V Round Belt Gates Serpentine Belt Ribbed Epdm Pk Belts China V Belt Timing Belt

Amazon Com Continental Oe Technology Series 4 Rib 37 2 Multi V Belt Automotive

Double Sided V Belts Din 7722

Gates 440j8 Micro V Belt J Section 440j Size 44 Length 3 4 Width 8 Rib Industrial V Belts Amazon Com Industrial Scientific

Dayco Poly V Serpentine Belts

Serpentine Or V Belt Driving Your Accessories Chevy Hardcore

V Belt Converted To Ribbed Belt Hutchinson Belt Drive Systems

What Is The Difference Between A V Belt And A Serpentine Belt Motor Vehicle Maintenance Repair Stack Exchange

Serpentine V Belts Vs Multi Ribbed Belts Auto Parts University

1

6 Ribbed Poly V Belt 48 Inch Micro Rib Groove Flat Belt Metric 480j6 480 J 6 Ebay

Accessory Drive Belts

A Scheme For V Ribbed Belts Download Scientific Diagram

Ribbed Belts

Diagnosing And Resolving Accessory Belt Problems Gates Europe

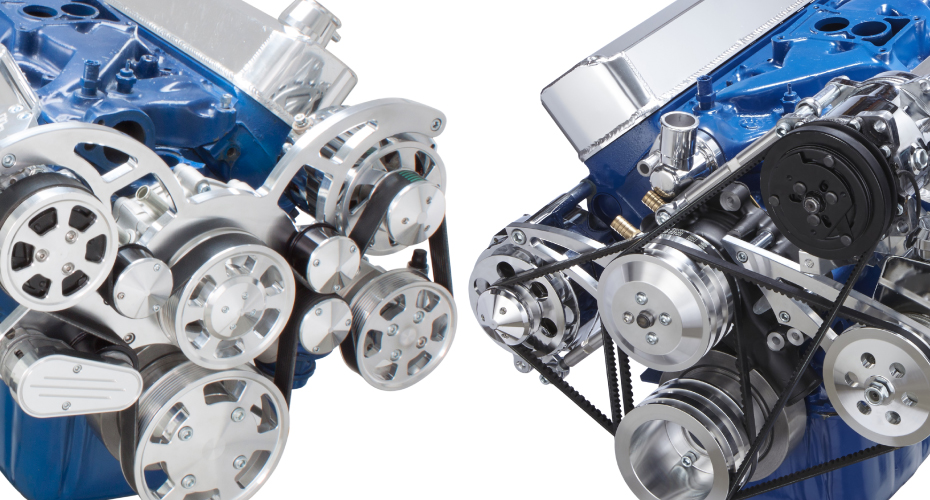

Tech Talk What S The Difference Serpentine Belts Vs V Belts Billet Kings

Serpentine Belts Vs V Belts Cvf Racing

Trp Ecatalogue

Ribbed Belts Vee Ribbed Belts Carlisle Belts Crp

Serpentine Or V Belt Driving Your Accessories Chevy Hardcore

360j10 V Ribbed V Belt 10 Ribs J10 36 O C Beltsmart

A Typical V Ribbed Belt 2 Download Scientific Diagram

Serpentine Belt Vs Timing Belt What Are The Differences

370j6 37inch 940mm 6 Ribs Poly Rib Belt Poly V Belt Mircro V Belt Poly Rib Belt Ribbed Beltpoly Belt Aliexpress

Dayton Micro Ribbed V Belt J 460j6 6 Ribs 46 In Outside Lg 9 16 In Top Wd 4 25 In Thick 3x655 3x655 Grainger

Drive Belt V Belt Iveco Stralis Cursor 10 Auto Ricambi Eu

China V Ribbed Belts Poly V Belts Multi Rib Belts Cogged Belts Wrapped Belts China V Belt Automotive Belt

Serpentine Belts What You Need To Know Allstate

Tech Tips For Measuring Lengths For V And Serpentine Accessory Drive Belts Holley Motor Life

Sincerely Durable Cheapest Price Epdm Poly V Ribbed Belt Pk Belt For Car Engine Parts Buy Pk V Belts V Ribbed Belts Multi Joint Narrow Pk Belt Product On Alibaba Com

Ribbed Belt Vee Rib Timken Belts Polyester For Heavy Duty Applications Anti Vibration

V Belt Vs Serpentine Benefits For Each Configuration Third Generation F Body Message Boards

Looking For Serpentine Belt Other Than Continental Bimmerfest Bmw Forum

Understanding Trade Offs When Selecting Belted Drive Systems

How To Check Belts In Your Car Yourmechanic Advice

Dayco Poly V Serpentine Belts

Switching From V Belts To Serpentine

Is The Continental Elite Poly V Belt Bs Or Is It Actually Better Than A Typical Serp Belt Mechanicadvice

Types Of Belts For Belt Drives Tec Science

Poly V Belts

508pj 0j Poly V Multiple Ribbed Belt J Section 2 34mm 508mm Long Ebay

559pj 2j Major Brand Poly V Multiple Ribbed Belt 559mm 22 Inch Length Simply Bearings Ltd

V Ribbed Belts Rib Ace Pl Bando Europe Gmbh

7 Symptoms Of A Bad Serpentine Belt And Replacement Cost In Easy Diy

Gates 540l8 Micro V Belt L Section 540l Size 54 Length 1 1 2 Width 8 Rib Industrial V Belts Amazon Com Industrial Scientific

B1745a Miscellaneous Replacement Belt V Belt Guys

1

Serpentine Belt Vs Timing Belt Everything You Need To Know

Amazon Com Gates K Micro V Serpentine Drive Belt Automotive

Serpentine Belt Tensioner Problems Signs Of Wear When To Replace Noises

Sun Unisol Brand Automotive Timing Belts V Ribbed Belts Pk Home Facebook

Robotic Mechanisms Pulleys And Belts Robotpark Academy

Poly V Belt For Industry Hutchinson Belt Drive Systems

Serpentine Belt Vs Timing Belt How Do They Differ

Automotive Belts Serpentine V Belt Cogged V Belt China Auto Parts Buy Belt Suppliers Manufacturers Exporters From Gasgoo Com

Shaft Drives

Types Of Belts For Belt Drives Tec Science

Double Sided Poly V Hutchinson Belt Drive Systems

Gates 300j4 Micro V Belt J Section 300j Size 30 Length 3 8 Width 4 Rib Industrial V Belts Amazon Com Industrial Scientific

Product Review Continental Elite Poly V Drive Belts Cadillac V Net

Serpentine Belt Vs Timing Belt How Do They Differ

How To Replace An Air Conditioning Belt Yourmechanic Advice

Serpentine Belt Wikipedia

Serpentine Belt System Wear 10 Tips For For Inspection Service

Drive Belt V Belt Iveco Trakker Auto Ricambi Eu

1000j24 Micro Rib Poly V Belt V Belt Guys

V Belt Pulleys Selection Guide Types Features Applications Engineering360

6pj356 140j 14inch 356mm Poly Rib Belt Pj Section Belt Treadmill Motor Drive Belt Mirco V Belt Poly Rib Belt Motor Drive Beltribbed Belt Aliexpress

1

Gates 230j10 Micro V Belt J Section 230j Size 23 Length 1 Width 10 Rib Industrial V Belts Amazon Com Industrial Scientific

0 件のコメント:

コメントを投稿